Understanding Diesel Generators: Definition and Core Components

What Constitutes a Diesel Generator?

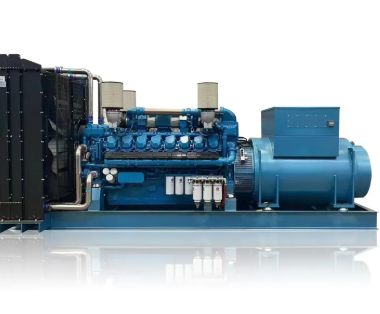

Diesel generators work by combining a diesel engine with what's called an electric generator or alternator to create electricity. People love them because they just keep going even when other things fail, which is why folks put them all over the place for main power or emergency backup situations. These machines come in every size imaginable really from those little portable ones people throw in the back of trucks to massive setups sitting on concrete pads at factories. That range of options means they fit almost anywhere needed. When there's a blackout or somewhere doesn't have regular electricity access, diesel gensets step in and keep things running smoothly. Looking at how these systems actually work reveals quite a bit about engineering ingenuity behind them, explaining why so many different industries rely on this technology despite all the alternatives available nowadays.

The Diesel Engine: Power Generation Core

At the core of every diesel generator sits the diesel engine itself, which transforms the energy stored in fuel into usable mechanical power. This basic process determines how well the generator produces electricity without wasting too much fuel. What makes diesel engines stand out? They're built tough and generally get better mileage than other options, which explains why they keep showing up in places where power needs to run nonstop for days or even weeks at a time. When looking at different engine designs like four stroke models compared to two stroke variants, there's actually quite a difference in what kind of output we get and how efficient those machines really are. That's why matching the right engine type to particular job requirements isn't just nice to have but absolutely necessary for getting good results. The whole reason diesel generators stay so widely used across emergency backup systems and remote locations boils down to these fundamental characteristics of their engines. Taking a closer look at various engine configurations helps anyone working with generators understand exactly what factors contribute most to overall system performance.

Alternator: Converting Mechanical to Electrical Energy

The alternator plays a really important role in diesel generators by turning mechanical energy into electrical power. Basically, it works through something called electromagnetic induction where the mechanical force from the running diesel engine gets transformed into usable electricity. When picking out an alternator, whether synchronous or asynchronous matters a lot because it affects how stable the electrical output will be and what kind of voltage levels we get. Getting these technical details right helps match the alternator to different power requirements and operating conditions. Making sure the alternator fits properly with the generator itself is crucial if we want optimal performance and to hit those target power outputs. Anyone looking at diesel generator options should take time to understand alternator specs before making a purchase decision.

Fuel and Lubrication Systems

A good fuel system matters a lot because it delivers diesel to the generator, which affects how well it runs and how much energy it uses. Most generators have either direct or indirect injection setups, and each has its own pros depending on what kind of workload they face daily. When fuel gets delivered properly, everything works better without those annoying hiccups during startup or sudden drops in power output. Lubrication isn't something people think about much either, but it keeps all those moving parts from grinding against each other too hard. Without enough oil circulating around, engines start wearing out faster than normal. That means longer life expectancy if someone actually remembers to check oil levels regularly. Choosing between wet and dry sump options depends largely on space constraints inside whatever facility houses these machines. Getting familiar with both systems makes sense for anyone who wants their diesel generator to keep running reliably year after year without breaking down unexpectedly at inconvenient times.

How Diesel Generators Work: The Four-Stage Process

Stage 1: Air Intake and Compression

When a diesel generator starts running, it begins with what we call the air intake phase. During this time, air gets pulled into those engine cylinders and then gets squeezed really tight, which makes both the pressure and temperature go way up inside there. This whole compression thing matters a lot because it actually affects how well the engine works and determines just how much power it can produce. If the compression ratio is higher during this process, the fuel burns better and the whole generator performs better too. Think about it like squeezing a sponge harder before wringing it out – more water comes out when you apply more pressure. That's basically what happens here with the fuel; more energy gets extracted from the same amount of fuel thanks to that increased compression.

Stage 2: Fuel Injection and Combustion

After compression comes fuel injection time. Diesel gets sprayed right into that super hot compressed air sitting inside the cylinder. The intense heat from compression sets off the diesel fuel, creating this big push that drives the piston downward. When it comes to when exactly to inject fuel and what kind of injection system to use (single shot or multiple shots), these decisions really matter for how clean and efficient the engine runs. Getting the timing just right makes all the difference for engine performance while keeping pollution levels low enough to satisfy today's strict emission regulations.

Stage 3: Mechanical Energy Generation

After burning the fuel, expanding gases push those pistons down inside the cylinder walls, turning the chemical stuff in diesel fuel into actual moving power. What happens next? That mechanical force gets passed along to the crankshaft, which basically takes all those vertical piston movements and turns them into spinning action instead. And it's this spinning power from the crankshaft that actually makes the alternator work, showing how everything starts with just plain old gas expanding in there. Without that initial explosion and expansion, none of the electricity generation would even happen in the first place.

Stage 4: Exhaust and Energy Conversion

When the engine reaches its last phase, the exhaust gases get pushed out, finishing what's basically the whole process of turning fuel into energy. A good exhaust system matters here because it helps cut down on harmful stuff going into the air and reduces how bad it is for the environment. What happens next is pretty interesting actually – those hot gases coming out can be captured and turned back into usable energy thanks to special exhaust setups. This makes diesel generators really good at what's called combined heat and power or CHP for short. So instead of just burning fuel and throwing away heat, these systems make sure most of that energy gets put to work somewhere else. The bottom line? Diesel generators still deliver solid power when needed, but they're doing it with better efficiency than ever before while producing fewer pollutants as well.

Primary Applications of Diesel Generators

Emergency Backup Power for Critical Facilities

Hospitals, data centers and many other essential buildings depend heavily on diesel generators when the main power goes down. These machines kick in almost instantly to keep lights on and equipment running during blackouts, which protects all sorts of operations that simply cannot stop. We see them installed everywhere from hospital wings to server rooms because they just work so reliably. When seconds count in an emergency situation, having those generators ready makes all the difference for patients in intensive care units or servers storing sensitive information. That's why facilities managers around the world continue to trust diesel generators despite newer alternatives coming onto the market.

Industrial and Construction Site Usage

For industrial work sites and construction projects, diesel generators offer reliable portable power that keeps tools running when needed most. These machines can keep going strong even when there's no connection to regular electricity grids, which happens all too often at remote job locations. That's why so many contractors prefer diesel over other options for temporary power needs. The engines themselves are pretty tough stuff, able to handle rough conditions without missing a beat. On actual construction sites, this means workers don't have to wait around for power outages to fix, and equipment stays productive throughout long days. Many field engineers will tell anyone who asks that having good backup power from diesel generators literally saves time and money on site.

Agricultural and Remote Area Electrification

For farmers, diesel generators play a vital role across many aspects of agriculture from running tractors and harvesters to powering irrigation pumps and farm lights, particularly in rural regions far from city power lines. These machines can handle tough conditions in isolated locations which really helps boost how much work gets done on farms day after day. When villages don't have reliable electricity connections, diesel generators become lifelines for keeping operations going without interruption during harvest seasons or planting periods. Most small scale farmers rely on these generators because they just keep working through dust storms, heatwaves, and whatever else Mother Nature throws at them. The result? Better crop yields and fewer losses due to sudden power cuts that would otherwise stop crucial processes mid-way.

Military and Disaster Response Scenarios

In both military operations and disaster response scenarios, diesel generators serve as critical power sources for communications equipment and other necessary field services. Built tough with durable components, these machines can withstand extreme weather conditions and rough terrain where most alternatives would fail. Military units stationed far from grid connections rely heavily on this technology, just as first responders need stable electricity when roads are blocked or infrastructure damaged. From desert bases to flood zones, the dependable output of diesel generators keeps command centers running, medical tents operational, and water purification systems active throughout crisis situations. This consistent energy availability often means the difference between successful mission outcomes and life-threatening delays in emergency responses.

Efficiency and Operational Considerations

Fuel Efficiency Compared to Gasoline Generators

When it comes to fuel efficiency, diesel generators really stand out compared to their gasoline counterparts, making them much better suited for extended periods of operation. Research shows time and again that these diesel engines burn less fuel while still producing plenty of power, so they make good financial sense in the long run. The money saved on fuel adds up fast, especially important for companies needing constant electricity supply without interruptions. Choosing diesel instead of gas means businesses aren't hit as hard when fuel prices jump around, which keeps those monthly expenses more predictable. For anyone looking at generator options, this cost stability alone makes diesel worth serious consideration despite higher upfront costs.

Continuous Runtime and Load Management

What really sets diesel generators apart is how they can run nonstop for hours on end, which makes them great for situations where power needs to last long. Gasoline units often need regular stops for fuel and maintenance checks, while diesel versions just keep going without much fuss. That kind of reliability matters a lot during emergencies or remote operations. Managing the electrical load properly is key to getting the best out of these machines. When operators spread out the power demand across different circuits and watch for overloads, the generator stays efficient and burns fuel at better rates. Getting this right means less wear and tear on the equipment too. Generators last longer this way, and businesses save money because breakdowns happen less frequently.

Maintenance Best Practices for Longevity

Keeping diesel generators well maintained really extends how long they last. Checking things like oil levels, filters, and cooling systems regularly makes sure everything keeps running smoothly. Putting together a solid maintenance plan cuts down on surprise breakdowns and generally makes the whole system work better. Preventive maintenance actually does two important things at once it makes generators more reliable while saving money in the long run because there are fewer expensive repairs needed and operations stay stable. People who follow good maintenance habits typically find that their diesel generators keep performing reliably year after year without major issues cropping up.

FAQ Section

What is a diesel generator?

A diesel generator is a device that combines a diesel engine and an electric generator to produce electrical energy. It's used widely for its reliability and efficiency.

Why are diesel generators considered reliable?

Diesel generators are seen as reliable due to their robust construction, superior fuel efficiency, and ability to provide consistent power over extended periods without requiring frequent maintenance.

How does a diesel engine work within a generator?

A diesel engine converts chemical energy from fuel into mechanical energy, which is then transformed into electrical energy by the alternator.

What are the main stages in the operation of a diesel generator?

The main stages include air intake and compression, fuel injection and combustion, mechanical energy generation, and exhaust and energy conversion.

What are the key applications of diesel generators?

Diesel generators are used for emergency backup power, industrial and construction site usage, agricultural and remote area electrification, and military and disaster response scenarios.