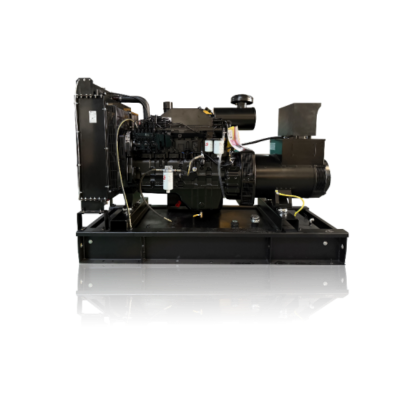

big generator diesel

Big generator diesel systems represent the pinnacle of reliable power generation technology, designed to deliver substantial electrical output for large-scale applications. These robust power solutions combine advanced diesel engine technology with high-capacity alternators to provide dependable electricity generation. Typically ranging from 500 kW to several megawatts, these generators feature sophisticated electronic control systems that monitor and optimize performance parameters including fuel consumption, temperature, and output voltage. The units incorporate heavy-duty cooling systems, precision fuel injection technology, and industrial-grade alternators to ensure consistent power delivery under demanding conditions. Modern big diesel generators include smart monitoring capabilities, allowing remote operation and real-time performance tracking. They are equipped with advanced safety features including automatic shutdown systems, fire detection, and emergency stop functions. The design prioritizes fuel efficiency through optimized combustion chambers and electronic fuel management systems, while also meeting current emission standards through integrated exhaust after-treatment systems. These generators serve as critical infrastructure in various sectors, from data centers and hospitals to industrial complexes and large commercial facilities, providing both primary and backup power solutions.