When power outages strike or reliable backup power becomes essential for your business operations, choosing the right diesel generator solution can make the difference between seamless continuity and costly downtime. The decision between portable and standby diesel generators involves careful consideration of your specific power requirements, budget constraints, and operational needs. Understanding the fundamental differences between these two generator types will help you make an informed investment that serves your power generation needs effectively for years to come.

Understanding Portable Diesel Generators

Core Features and Design Characteristics

Portable diesel generators are designed for mobility and flexibility, featuring wheeled frames, lifting points, and compact construction that enables transportation between job sites or storage locations. These units typically range from 5kVA to 50kVA output capacity, making them suitable for construction sites, outdoor events, emergency backup power, and temporary installations. The robust diesel engine paired with an alternator provides reliable power generation while maintaining fuel efficiency that diesel engines are renowned for delivering consistently.

Most portable models incorporate weather-resistant enclosures that protect internal components from environmental exposure while maintaining accessibility for routine maintenance and operation. Advanced portable units feature digital control panels, automatic voltage regulation, and sophisticated monitoring systems that rival their stationary counterparts. The fuel tank capacity typically provides 8-12 hours of continuous operation at rated load, though this varies significantly based on the specific model and manufacturer specifications.

Operational Advantages and Applications

The primary advantage of portable diesel generators lies in their versatility and ability to provide power wherever needed most. Construction companies frequently deploy these units to remote job sites where grid connection is unavailable or impractical, while event organizers rely on them for outdoor venues lacking adequate electrical infrastructure. Emergency response teams and disaster relief organizations depend on portable generators to establish temporary power supplies in affected areas quickly and efficiently.

Fuel availability represents another significant operational advantage, as diesel fuel is widely accessible and offers superior energy density compared to gasoline alternatives. Diesel engines deliver exceptional fuel efficiency, often consuming 30-50% less fuel than comparable gasoline generators while providing longer continuous runtime between refueling cycles. This efficiency translates into lower operational costs and reduced maintenance requirements over the generator's operational lifespan.

Exploring Standby Diesel Generator Systems

Permanent Installation Features

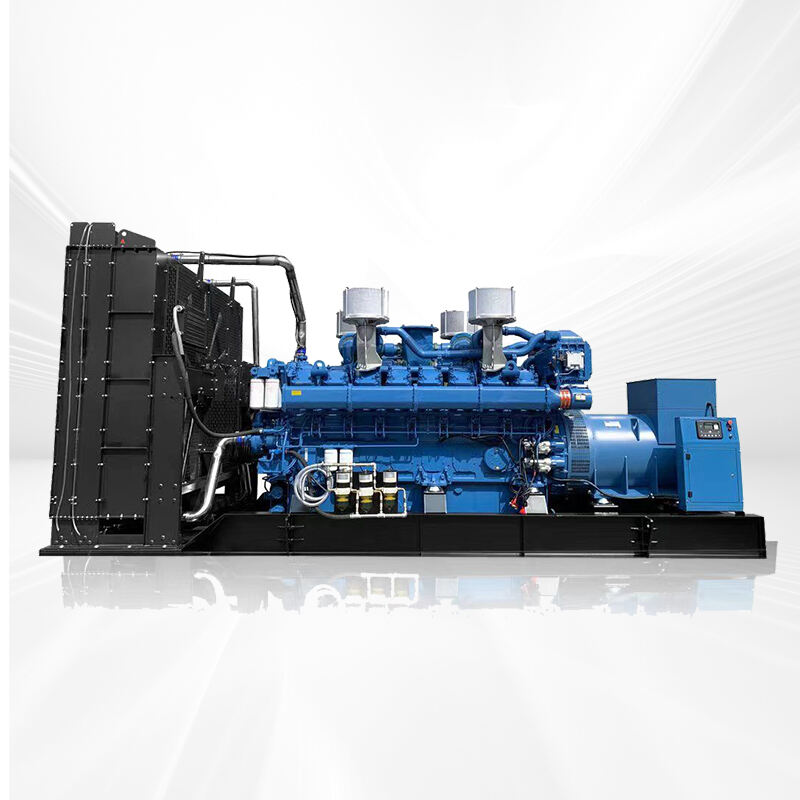

Standby diesel generators are permanently installed systems designed to provide automatic backup power during utility outages or grid failures. These systems integrate seamlessly with existing electrical infrastructure through automatic transfer switches that detect power loss and initiate generator startup within seconds. Professional installation includes concrete pads, weatherproof enclosures, fuel supply systems, and comprehensive electrical connections that enable fully automated operation without human intervention required.

Large capacity standby units often feature sophisticated engine management systems, remote monitoring capabilities, and advanced diagnostics that enable predictive maintenance scheduling. The fuel systems typically include day tanks, bulk storage options, and automatic fuel delivery systems that ensure continuous operation during extended outages. These comprehensive installations represent significant capital investments but deliver unparalleled reliability for mission-critical applications where power interruption cannot be tolerated.

Commercial and Industrial Applications

Hospitals, data centers, manufacturing facilities, and other critical infrastructure depend on standby diesel generator systems to maintain operations during utility failures. These installations often require custom engineering to accommodate specific load requirements, redundancy needs, and regulatory compliance standards. The automatic startup and load transfer capabilities ensure seamless power transitions that protect sensitive equipment and maintain operational continuity without manual intervention.

Financial institutions, telecommunications facilities, and government buildings frequently specify standby generators as essential infrastructure components rather than optional backup systems. These installations undergo rigorous testing schedules and maintenance protocols to ensure reliability when needed most. The substantial initial investment is justified by the catastrophic costs associated with power outages in these mission-critical environments.

Performance Comparison and Selection Criteria

Power Output and Load Management

Portable generators typically provide single-phase or three-phase power output ranging from 5kVA to 100kVA, with most units optimized for resistive loads and standard electrical equipment. Load management becomes crucial with portable units, as exceeding rated capacity can damage both the generator and connected equipment. Users must carefully calculate total connected load and consider starting surges from motors and other inductive loads when selecting appropriate capacity.

Standby systems offer significantly higher power output capabilities, often ranging from 20kVA to several megawatts for large industrial installations. These systems incorporate sophisticated load management features including automatic load shedding, priority load sequencing, and soft-start capabilities that optimize power distribution during startup and operation. The permanent installation enables precise load calculations and engineered solutions that maximize efficiency while ensuring adequate capacity reserves.

Fuel Efficiency and Operating Costs

Diesel generator fuel consumption varies significantly between portable and standby configurations, influenced by engine size, load factor, and operational efficiency. Portable units typically consume 2-4 liters per hour at rated load, while larger standby systems may consume 20-50 liters per hour depending on capacity and load conditions. The superior fuel efficiency of diesel engines compared to gasoline alternatives makes them particularly attractive for extended runtime applications where fuel costs represent significant operational expenses.

Operating cost analysis must include fuel consumption, maintenance requirements, replacement parts, and labor costs associated with routine service procedures. Portable generators require more frequent maintenance due to variable operating conditions and transportation stresses, while standby systems benefit from controlled environments and predictable operating patterns. Professional maintenance contracts for standby installations often provide cost predictability and ensure compliance with warranty requirements and regulatory standards.

Installation and Maintenance Requirements

Setup and Infrastructure Needs

Portable diesel generator installation involves minimal infrastructure requirements, typically needing only level ground, adequate ventilation, and appropriate electrical connections for load transfer. Most portable units can be operational within hours of delivery, making them ideal for emergency applications or temporary power needs. However, proper grounding, fuel storage, and safety protocols must be established to ensure safe and compliant operation in any installation environment.

Standby generator installations require comprehensive planning including site preparation, utility coordination, permitting processes, and professional electrical connections. Foundation requirements, fuel system installation, automatic transfer switch integration, and load center modifications represent substantial additional costs beyond the generator unit itself. Local building codes and utility regulations often mandate specific installation requirements that must be addressed through professional engineering and certified installation contractors.

Maintenance Protocols and Service Requirements

Regular maintenance schedules for diesel generators include oil changes, fuel system servicing, air filter replacement, coolant system maintenance, and battery testing regardless of portable or standby configuration. Portable units may require more frequent attention due to variable operating conditions, transportation stresses, and exposure to harsh environmental conditions during deployment. Service intervals typically range from 100-500 hours of operation or annually, whichever occurs first, depending on manufacturer specifications and operating environment.

Standby systems benefit from controlled operating environments but require comprehensive preventive maintenance programs to ensure reliability when needed. Professional service contracts often include regular testing schedules, computerized maintenance management, parts inventory management, and emergency service capabilities. The investment in professional maintenance programs pays dividends through improved reliability, extended equipment life, and maintained warranty coverage throughout the operational period.

Cost Analysis and Return on Investment

Initial Investment Considerations

Portable diesel generator costs typically range from several thousand dollars for small units to tens of thousands for large capacity models, representing relatively modest initial investments compared to standby alternatives. The total cost of ownership includes the generator unit, basic accessories, fuel storage, and minimal installation requirements that can often be accomplished without professional contractors. This lower barrier to entry makes portable generators attractive for small businesses, residential applications, and organizations with limited capital budgets.

Standby generator systems require substantially higher initial investments that include the generator unit, automatic transfer switch, professional installation, site preparation, fuel system infrastructure, and often electrical system modifications. Total project costs frequently range from tens of thousands to hundreds of thousands of dollars depending on capacity, complexity, and site-specific requirements. However, this investment delivers automated operation, higher reliability, and seamless integration that justifies the premium for critical applications.

Long-term Value and Economic Benefits

Economic analysis of generator investments must consider the cost of power outages, including lost productivity, damaged equipment, spoiled inventory, and business interruption expenses. For many commercial and industrial applications, a single extended outage can cost more than the entire generator investment, making standby systems clearly justified from a financial perspective. The automatic operation and higher reliability of standby installations provide superior protection against these potentially catastrophic losses.

Portable generators offer excellent value for applications where outage costs are moderate and flexibility is prioritized over automation. The ability to deploy portable units where needed most, share resources between multiple locations, and avoid permanent installation costs makes them economically attractive for many applications. Rental options for portable generators provide additional flexibility for temporary needs or organizations evaluating long-term power requirements before committing to permanent installations.

FAQ

What size diesel generator do I need for my facility

Determining the appropriate generator size requires calculating your total electrical load including lighting, HVAC systems, critical equipment, and motors with their starting surge requirements. A qualified electrical contractor should perform a comprehensive load analysis considering demand factors, future expansion plans, and emergency load prioritization to specify the optimal generator capacity. Generally, you should size the generator at 125% of your calculated load to provide adequate safety margin and account for power factor considerations.

How often should diesel generators be serviced

Diesel generators require regular maintenance every 100-500 operating hours or annually, whichever comes first, depending on the manufacturer specifications and operating conditions. Essential service items include engine oil and filter changes, fuel system cleaning, air filter replacement, coolant system maintenance, battery testing, and comprehensive system inspections. Standby generators that rarely operate may require more frequent testing and exercise cycles to ensure readiness, while heavily used portable units need more frequent oil changes and component inspections.

Can portable diesel generators run continuously

Most portable diesel generators are designed for continuous duty operation when properly maintained and operated within their rated specifications. Continuous runtime is primarily limited by fuel tank capacity, typically providing 8-24 hours of operation depending on load and tank size. For extended continuous operation, external fuel tanks or fuel delivery systems can be connected to provide indefinite runtime capability. However, regular maintenance intervals and component replacement schedules must be followed regardless of continuous operation requirements.

What permits are required for standby generator installation

Standby generator installations typically require building permits, electrical permits, and potentially environmental permits depending on generator size and local regulations. Many jurisdictions require professional engineering design, certified electrical contractor installation, and utility coordination for automatic transfer switch connections. Fire department approval may be necessary for fuel storage systems, while environmental regulations may apply to exhaust systems and noise levels. Consulting with local authorities early in the planning process ensures compliance with all applicable requirements and avoids costly delays or modifications.