When it comes to powering critical operations during outages or in remote locations, selecting the right generator engine becomes paramount for businesses and industries worldwide. A reliable generator engine serves as the heart of any power generation system, determining not only the unit's performance but also its longevity, fuel efficiency, and maintenance requirements. The market offers numerous options from established manufacturers, each promising superior reliability and performance characteristics that can make the selection process challenging for procurement professionals and facility managers.

Understanding the key factors that distinguish reliable generator engine brands helps organizations make informed decisions that align with their operational requirements and budget constraints. These factors include manufacturing heritage, technological innovation, global service network availability, and proven track records across diverse applications. The following comprehensive analysis examines the most trusted names in the industry, providing insights into their strengths, applications, and what makes them stand out in the competitive landscape of power generation equipment.

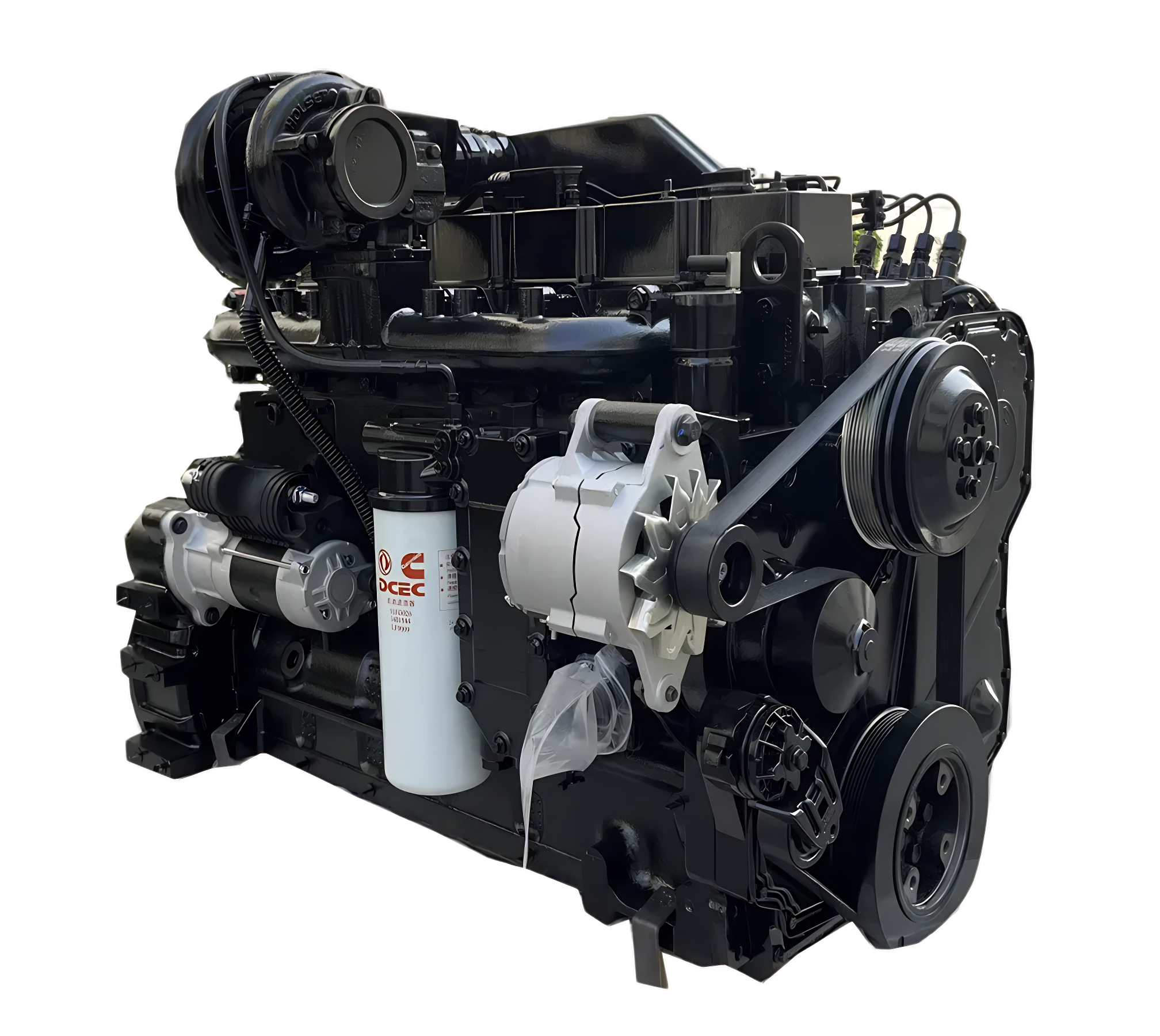

Cummins Engines: Industry Leadership and Innovation

Heritage and Market Position

Cummins has established itself as a dominant force in the generator engine market through decades of continuous innovation and reliable performance. Founded in 1919, the company has built an impressive reputation for producing robust diesel engines that excel in demanding applications. Their generator engine lineup spans from small residential units to massive industrial installations, demonstrating versatility that few competitors can match. The brand's commitment to research and development has resulted in engines that consistently meet stringent emission standards while delivering exceptional fuel economy and operational reliability.

The company's global presence ensures comprehensive support for customers worldwide, with service centers and parts availability in virtually every major market. This extensive network proves invaluable for organizations operating in remote locations or requiring rapid response times for maintenance and repairs. Cummins engines power everything from hospital backup systems to data centers, mining operations, and marine applications, showcasing their adaptability across diverse industries and operating conditions.

Technical Excellence and Performance Characteristics

Cummins generator engines incorporate advanced fuel injection systems, sophisticated electronic controls, and precision manufacturing techniques that contribute to their reputation for reliability. The company's engines feature robust construction with heavy-duty components designed to withstand continuous operation under varying load conditions. Their electronic control modules provide real-time monitoring and diagnostic capabilities, enabling predictive maintenance strategies that minimize unexpected downtime and extend engine life.

The brand's focus on environmental compliance has led to breakthrough technologies in emission reduction without compromising performance. Their Tier 4 Final compliant engines utilize selective catalytic reduction and diesel particulate filters to achieve ultra-low emissions while maintaining the power density and fuel efficiency that customers expect. This environmental consciousness positions Cummins engines favorably for organizations prioritizing sustainability goals alongside operational requirements.

Caterpillar Engines: Heavy-Duty Reliability

Construction and Mining Heritage

Caterpillar brings decades of experience from the construction and mining industries to their generator engine offerings, resulting in products engineered for extreme durability and continuous operation. The company's expertise in developing engines for harsh environments translates directly to generator applications where reliability cannot be compromised. Their engines are designed with oversized components, advanced cooling systems, and robust filtration to handle extended runtime requirements common in industrial and commercial applications.

The integration of Caterpillar's proprietary technologies, including their Advanced Combustion Emission Reduction Technology, ensures optimal performance while meeting environmental regulations. Their engines feature electronic control systems that optimize fuel delivery, timing, and emissions control for maximum efficiency across varying load conditions. This sophisticated approach to engine management contributes to lower operating costs and reduced environmental impact without sacrificing the reliability that customers demand.

Caterpillar's commitment to continuous improvement shows in their regular introduction of enhanced engine designs incorporating lessons learned from field applications. Their generator engine lineup benefits from innovations developed for mobile equipment, creating synergies that accelerate technological advancement. The company's extensive dealer network provides comprehensive support services, including emergency repair capabilities that prove crucial for mission-critical applications.

Power Range and Application Versatility

The breadth of Caterpillar's generator engine portfolio covers an impressive range from small commercial units to multi-megawatt industrial installations. This comprehensive offering allows customers to standardize on a single brand across diverse applications, simplifying maintenance training, parts inventory, and service relationships. Their engines excel in applications requiring high power density, such as marine propulsion, oil and gas operations, and large-scale backup power systems for critical facilities.

Caterpillar's modular approach to generator design enables custom configurations that meet specific customer requirements while maintaining standardized components for cost-effective maintenance. Their engines incorporate advanced monitoring systems that provide detailed operational data, enabling optimization of maintenance schedules and early detection of potential issues. This data-driven approach to engine management helps customers maximize uptime while controlling operating costs.

Perkins Engines: Compact Power Solutions

Specialization in Smaller Displacement Engines

Perkins has carved out a significant niche in the generator engine market by focusing on compact, efficient engines that deliver impressive power-to-weight ratios. The company's heritage in developing engines for agricultural and industrial equipment provides a solid foundation for their generator applications. Their engines are particularly well-suited for mobile generator sets, backup power systems for small to medium businesses, and applications where space constraints limit engine size options.

The brand's emphasis on fuel efficiency resonates strongly with customers facing rising fuel costs and environmental concerns. Perkins engines incorporate advanced fuel injection technologies and optimized combustion chamber designs that extract maximum energy from each drop of fuel. Their electronic control systems continuously adjust operating parameters to maintain peak efficiency across varying load conditions, resulting in lower operating costs and reduced carbon footprint for end users.

Global Manufacturing and Support Infrastructure

Perkins operates manufacturing facilities worldwide, enabling localized production that reduces costs and delivery times while ensuring consistent quality standards. Their global footprint includes dedicated generator engine production lines that incorporate specialized manufacturing processes optimized for stationary power applications. This focused approach results in engines specifically engineered for generator duty cycles rather than adapted from mobile applications.

The company's commitment to customer support includes comprehensive training programs for technicians and comprehensive documentation that simplifies maintenance procedures. Their parts distribution network ensures rapid availability of replacement components, minimizing downtime when service is required. Perkins also offers extensive warranty coverage that demonstrates confidence in their product reliability while providing customers with peace of mind regarding their investment protection.

Deutz Engines: German Engineering Excellence

Air-Cooled Technology Leadership

Deutz stands out in the generator engine market through their expertise in air-cooled engine technology, offering solutions that eliminate the complexity and potential failure points associated with liquid cooling systems. Their air-cooled generator engines provide significant advantages in applications where cooling water availability is limited or where simplified maintenance procedures are prioritized. This technology proves particularly valuable in remote installations, mobile applications, and environments where freezing temperatures could compromise liquid cooling systems.

The company's German engineering heritage emphasizes precision manufacturing, robust construction, and attention to detail that results in engines capable of extended operation with minimal maintenance intervention. Deutz engines feature heavy-duty construction with generous service intervals that reduce maintenance costs and improve overall system availability. Their commitment to continuous improvement has led to advanced fuel injection systems and electronic controls that optimize performance while maintaining the simplicity that makes their engines attractive for diverse applications.

Environmental Compliance and Efficiency

Deutz has invested heavily in developing clean-burning generator engines that meet strict emission standards without compromising reliability or performance. Their engines incorporate sophisticated after-treatment systems when required, while optimizing combustion processes to minimize emissions at the source. This dual approach ensures compliance with environmental regulations while maintaining the durability and low maintenance characteristics that customers expect from Deutz products.

The company's focus on fuel efficiency extends beyond environmental considerations to address the economic concerns of end users. Their generator engines deliver competitive fuel consumption rates through advanced combustion chamber designs, precise fuel injection timing, and electronic controls that continuously optimize operating parameters. This attention to efficiency helps customers control operating costs while meeting their power generation requirements reliably and consistently.

Volvo Penta Engines: Marine-Derived Durability

Marine Heritage Applied to Stationary Power

Volvo Penta brings extensive marine engine experience to the generator market, resulting in products engineered for continuous operation under demanding conditions. Their generator engines benefit from technologies developed for marine applications where reliability is absolutely critical and service access may be limited. This heritage translates to robust construction, advanced corrosion protection, and sophisticated monitoring systems that ensure dependable operation in challenging environments.

The company's expertise in developing engines for commercial marine applications provides valuable insights into optimizing generator engine performance for extended runtime applications. Their engines feature oversized cooling systems, heavy-duty construction, and advanced filtration that contribute to exceptional durability and extended service intervals. Volvo Penta's commitment to continuous operation reliability makes their engines particularly attractive for critical backup power applications and prime power installations where downtime consequences are severe.

Advanced Electronic Systems and Connectivity

Volvo Penta leads the industry in integrating advanced electronic control and monitoring systems into their generator engines. Their proprietary engine management systems provide comprehensive real-time monitoring of all critical parameters while enabling remote diagnostics and predictive maintenance capabilities. These sophisticated systems help customers optimize performance, extend component life, and minimize unscheduled maintenance through early detection of developing issues.

The company's investment in connectivity solutions enables integration with modern facility management systems and remote monitoring platforms. Their engines can provide detailed operational data, performance trends, and maintenance alerts through various communication protocols, enabling proactive maintenance strategies that maximize uptime while controlling costs. This technological leadership positions Volvo Penta engines favorably for customers seeking advanced monitoring and control capabilities in their power generation systems.

Selection Criteria for Generator Engines

Performance and Reliability Factors

Selecting the optimal generator engine requires careful evaluation of multiple performance characteristics that directly impact operational success and total cost of ownership. Power output consistency across varying load conditions represents a fundamental requirement, as voltage and frequency stability determine whether sensitive equipment can operate reliably on generator power. Engine manufacturers provide detailed performance curves that illustrate how their engines maintain power quality under different loading scenarios, information that proves crucial for applications involving sophisticated electronic equipment.

Fuel efficiency considerations extend beyond simple consumption rates to include performance under partial load conditions, which represents the majority of operating time for most backup power applications. Generator engines that maintain high efficiency at 25-50% loading provide significant operational cost advantages over units optimized only for full-load operation. Additionally, cold start capabilities, warm-up time requirements, and response to sudden load changes all influence system reliability and user satisfaction with generator performance.

Maintenance and Service Considerations

The availability of qualified service technicians and genuine replacement parts significantly impacts the long-term viability of any generator engine selection. Manufacturers with comprehensive dealer networks and established service infrastructure provide advantages through reduced response times, standardized service procedures, and access to factory-trained technicians. Organizations operating multiple generator systems particularly benefit from standardizing on engine brands with strong local support capabilities and consistent parts availability.

Service interval lengths and maintenance complexity directly affect operational costs and system availability over the generator's service life. Generator engines designed with extended maintenance intervals and simplified service procedures reduce both scheduled downtime and maintenance expenses. Modern engines incorporate condition-based maintenance capabilities that optimize service scheduling based on actual operating conditions rather than fixed time intervals, further improving system availability and cost control.

FAQ

What factors should be prioritized when selecting a generator engine brand

The most important factors include proven reliability in similar applications, availability of local service support, fuel efficiency characteristics, and total cost of ownership calculations. Consider the manufacturer's track record, warranty coverage, parts availability, and service network strength in your operating region. Additionally, evaluate emission compliance requirements, noise levels, and integration capabilities with your existing systems. The generator engine's expected duty cycle and load profile should align with the manufacturer's design specifications to ensure optimal performance and longevity.

How do maintenance requirements vary between different generator engine brands

Maintenance requirements can vary significantly between brands based on their design philosophy, component quality, and operating environment specifications. Some manufacturers focus on extended service intervals with more complex maintenance procedures, while others emphasize frequent but simple maintenance tasks. Air-cooled engines typically require more frequent air filter changes but eliminate cooling system maintenance. Electronic control systems add diagnostic capabilities but may require specialized training for service technicians. Review detailed maintenance schedules and consider technician availability when comparing options.

What role does fuel type compatibility play in engine selection

Fuel compatibility affects both initial cost and long-term operational flexibility, as different generator engines may be optimized for specific fuel types or grades. Diesel engines generally offer superior fuel efficiency and longevity but require higher initial investment compared to natural gas alternatives. Some engines offer dual-fuel capabilities that provide operational flexibility and fuel cost optimization opportunities. Consider local fuel availability, storage requirements, environmental regulations, and long-term fuel cost projections when evaluating fuel compatibility options for your specific application.

How important is emissions compliance in generator engine selection

Emissions compliance requirements vary by location, application, and installation date, making it essential to verify current and anticipated future regulations before making engine selections. Non-compliant engines may face operating restrictions, retrofit requirements, or replacement mandates that significantly impact total cost of ownership. Modern compliant engines incorporate sophisticated after-treatment systems that require periodic maintenance and specialized service procedures. Consider both current regulatory requirements and likely future changes when evaluating emissions compliance for long-term installations.