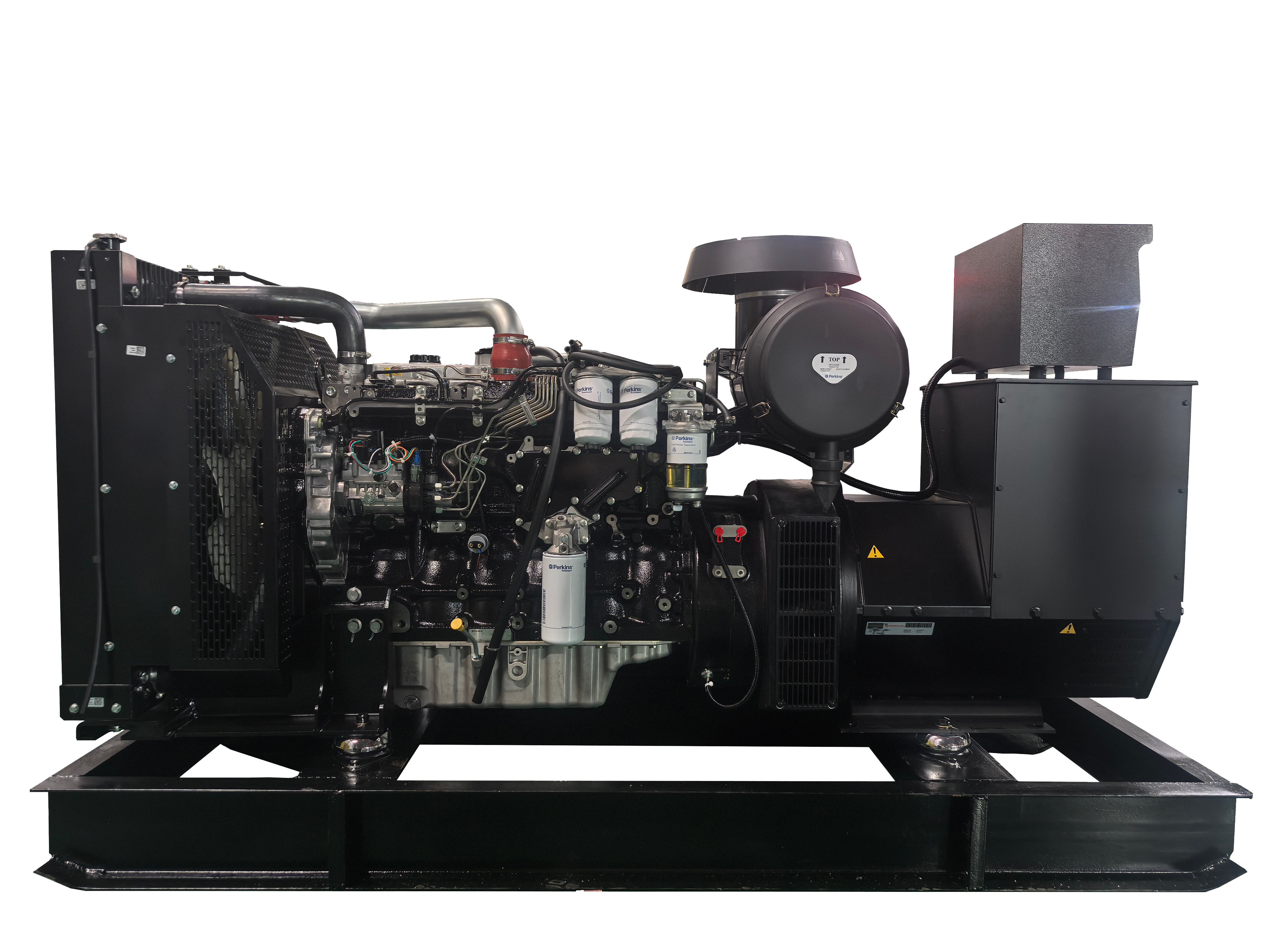

When selecting reliable backup power solutions for industrial and commercial applications, few brands command the respect and trust that Perkins diesel generators have earned over decades of proven performance. These robust power generation systems have become the backbone of critical operations across construction sites, manufacturing facilities, data centers, and emergency response scenarios worldwide. Understanding the key factors that make a perkins generator the preferred choice for demanding applications requires examining both the technical specifications and real-world performance characteristics that set these units apart from competitors.

The evolution of power generation technology has consistently demonstrated that engine reliability forms the foundation of any successful generator system. Perkins engines have established themselves as industry leaders through continuous innovation in fuel efficiency, emissions control, and operational durability. This comprehensive guide explores the essential considerations for selecting the optimal generator configuration, maintenance requirements, and performance expectations that buyers should evaluate before making their investment decision.

Understanding Perkins Engine Technology

Advanced Combustion Systems

The heart of every reliable generator lies in its engine technology, and Perkins has consistently pushed the boundaries of diesel engine innovation. Their latest combustion systems incorporate advanced fuel injection timing, optimized cylinder head designs, and precision-engineered components that deliver exceptional power density while maintaining fuel economy. These technological improvements translate directly into reduced operating costs and extended service intervals for end users.

Modern Perkins engines feature electronic control systems that continuously monitor and adjust operating parameters to maintain optimal performance across varying load conditions. This intelligent management system ensures consistent power output while protecting critical engine components from potentially damaging operating conditions. The integration of these advanced systems has significantly improved the reliability and longevity of contemporary generator installations.

Emissions Compliance and Environmental Performance

Environmental regulations have become increasingly stringent across global markets, driving the development of cleaner-burning engine technologies. Perkins has responded to these challenges by developing engines that meet or exceed current emissions standards while maintaining the performance characteristics that customers demand. Their staged combustion technology and advanced after-treatment systems work together to minimize harmful emissions without compromising power output.

The implementation of selective catalytic reduction systems and diesel particulate filters in modern Perkins engines demonstrates their commitment to environmental responsibility. These technologies not only ensure regulatory compliance but also contribute to improved fuel efficiency and reduced maintenance requirements. Understanding these environmental considerations becomes crucial when selecting generators for installations in areas with strict emission regulations.

Power Rating and Application Matching

Determining Appropriate Generator Sizing

Selecting the correct power rating represents one of the most critical decisions in the generator procurement process. Undersized units struggle to meet peak demand requirements, while oversized systems operate inefficiently and incur unnecessary initial and operating costs. Proper load analysis involves examining both steady-state power requirements and transient load conditions that occur during equipment startup or peak operational periods.

Professional load calculations must account for power factor considerations, harmonic distortion from electronic loads, and future expansion requirements. Many applications benefit from generators with 20-25% capacity above calculated maximum demand to ensure reliable operation and accommodate unexpected load increases. This sizing philosophy provides operational flexibility while maintaining fuel efficiency during typical operating conditions.

Standby versus Prime Power Applications

The distinction between standby and prime power applications significantly influences generator selection and configuration requirements. Standby generators typically operate only during utility outages and must provide reliable emergency power for critical systems. These units often feature automatic start systems, transfer switches, and monitoring equipment that enables unattended operation during extended power outages.

Prime power applications require generators to operate continuously as the primary power source, demanding enhanced cooling systems, larger fuel tanks, and more robust electrical components. perkins generator configurations for prime power service incorporate heavy-duty alternators, reinforced engine mounts, and extended warranty coverage that reflects their demanding operational requirements. Understanding these application differences ensures appropriate equipment selection and optimal long-term performance.

Key Selection Criteria and Performance Features

Fuel System Design and Efficiency

Fuel system architecture plays a crucial role in determining overall generator performance and operational costs. Modern Perkins generators incorporate common rail fuel injection systems that deliver precise fuel metering across all operating conditions. These advanced systems optimize combustion efficiency while reducing fuel consumption and emissions output compared to conventional injection technologies.

The integration of fuel filtration systems, water separation components, and fuel conditioning equipment ensures consistent fuel quality reaches the engine. Proper fuel system design prevents contamination-related failures while extending component service life. Additionally, fuel monitoring systems provide real-time consumption data that enables accurate operating cost calculations and maintenance scheduling.

Cooling System Performance and Reliability

Effective cooling system design directly impacts generator reliability and service life in demanding applications. Perkins generators feature oversized cooling systems with redundant cooling capacity to handle extreme ambient conditions and sustained high-load operation. Radiator designs incorporate corrosion-resistant materials and fin configurations optimized for airflow efficiency and debris resistance.

Advanced cooling system monitoring prevents overheating conditions through automatic load reduction and shutdown protection systems. These safety features protect expensive engine components while providing operators with early warnings of potential cooling system issues. Regular cooling system maintenance, including coolant analysis and heat exchanger cleaning, ensures continued reliable operation throughout the generator's service life.

Maintenance Requirements and Service Support

Scheduled Maintenance Programs

Successful generator operation depends heavily on adherence to manufacturer-recommended maintenance schedules and procedures. Perkins generators benefit from comprehensive maintenance programs that address engine servicing, electrical system inspection, and cooling system care. These programs typically include oil and filter changes, coolant system service, battery maintenance, and comprehensive system testing protocols.

Preventive maintenance intervals vary based on operating hours, load factors, and environmental conditions. Standby generators may require less frequent service than prime power units, but both applications benefit from regular exercise and system testing. Establishing relationships with qualified service providers ensures access to genuine parts, technical expertise, and emergency repair capabilities when needed.

Parts Availability and Technical Support

The global availability of genuine Perkins parts and technical support represents a significant advantage for generator owners. Their extensive dealer network provides local access to replacement components, technical documentation, and factory-trained service technicians. This support infrastructure minimizes downtime during maintenance events and ensures rapid response to unexpected service requirements.

Modern diagnostic systems integrated into Perkins generator controls provide detailed fault codes and system status information that facilitates rapid troubleshooting. Remote monitoring capabilities enable service providers to track generator performance and schedule maintenance based on actual operating conditions rather than fixed time intervals. This data-driven approach optimizes maintenance costs while ensuring reliable operation.

Installation Considerations and Best Practices

Site Preparation and Environmental Factors

Proper site preparation forms the foundation for reliable generator operation and longevity. Installation sites must provide adequate ventilation for combustion air and cooling system airflow while protecting equipment from environmental hazards. Concrete pads require proper design to handle static loads and vibration isolation systems that prevent structure-borne noise transmission.

Environmental considerations include protection from weather exposure, flood potential, and security requirements. Outdoor installations benefit from weather-resistant enclosures that provide protection while maintaining necessary airflow and service access. Indoor installations require adequate ventilation systems for combustion air supply and exhaust gas removal to prevent dangerous carbon monoxide accumulation.

Electrical Integration and Safety Systems

Electrical integration of generator systems requires careful coordination with existing facility electrical systems and safety requirements. Automatic transfer switches must provide reliable switching between utility and generator power while preventing dangerous backfeed conditions. Ground fault protection, overcurrent protection, and emergency shutdown systems ensure safe operation and compliance with electrical codes.

Modern generator control systems integrate with building management systems to provide centralized monitoring and control capabilities. These systems enable remote operation, performance monitoring, and alarm notification that enhances operational efficiency while reducing the need for on-site personnel during generator operation. Proper electrical design ensures seamless integration with existing facility systems and future expansion requirements.

Cost Analysis and Return on Investment

Initial Investment Considerations

Generator procurement costs extend beyond the initial equipment purchase to include installation, commissioning, and integration expenses. Proper cost analysis must account for site preparation requirements, electrical infrastructure modifications, and permitting costs that vary significantly based on installation complexity and local regulations. Additionally, fuel system installation, exhaust system design, and noise abatement measures contribute to total project costs.

Financing options and warranty coverage significantly impact the total cost of ownership calculations. Extended warranty programs provide protection against unexpected repair costs while service agreements ensure proper maintenance and optimal performance. Evaluating these financial considerations alongside equipment specifications enables informed decision-making that balances initial investment with long-term operational costs.

Operating Cost Projections

Accurate operating cost projections require analysis of fuel consumption, maintenance expenses, and potential revenue impacts of power outages. Fuel efficiency improvements in modern perkins generator designs significantly reduce operating costs compared to older technology. Additionally, extended service intervals and improved component reliability contribute to lower maintenance costs over the equipment's service life.

Business continuity benefits often justify generator investments through avoided losses during power outages. Manufacturing facilities, data centers, and healthcare facilities face significant financial and operational impacts from power interruptions that far exceed generator operating costs. Quantifying these potential losses provides perspective on the value proposition of reliable backup power systems.

FAQ

What factors determine the appropriate size for a Perkins generator installation

Generator sizing requires comprehensive analysis of both steady-state and transient power demands, including equipment starting currents, power factor considerations, and future expansion plans. Professional load calculations should account for critical versus non-critical loads, operating schedules, and peak demand periods. Most applications benefit from 20-25% capacity above calculated maximum demand to ensure reliable operation and accommodate unexpected load increases while maintaining fuel efficiency.

How do maintenance requirements differ between standby and prime power generator applications

Standby generators typically require maintenance based on calendar intervals and exercise hours, while prime power units follow maintenance schedules based on actual operating hours and load factors. Prime power applications demand more frequent oil changes, filter replacements, and cooling system service due to continuous operation. Both applications benefit from regular system testing, but prime power units require more comprehensive monitoring and preventive maintenance to ensure reliable continuous operation.

What are the key advantages of modern Perkins generator technology compared to older systems

Modern Perkins generators incorporate advanced electronic control systems, improved fuel injection technology, and enhanced emissions control systems that deliver superior fuel efficiency and reduced environmental impact. Electronic monitoring and diagnostic capabilities enable predictive maintenance strategies while automatic protection systems prevent damage from operating anomalies. Additionally, improved cooling system designs and component materials extend service life and reduce maintenance requirements compared to older generator technologies.

How important is local service support when selecting a generator supplier

Local service support represents a critical factor in generator selection, particularly for mission-critical applications where rapid response times are essential. Access to factory-trained technicians, genuine replacement parts, and emergency service capabilities significantly impacts equipment reliability and operational costs. Perkins' extensive global dealer network provides consistent service quality and parts availability that ensures minimal downtime during maintenance events and unexpected service requirements throughout the generator's operational life.

Table of Contents

- Understanding Perkins Engine Technology

- Power Rating and Application Matching

- Key Selection Criteria and Performance Features

- Maintenance Requirements and Service Support

- Installation Considerations and Best Practices

- Cost Analysis and Return on Investment

-

FAQ

- What factors determine the appropriate size for a Perkins generator installation

- How do maintenance requirements differ between standby and prime power generator applications

- What are the key advantages of modern Perkins generator technology compared to older systems

- How important is local service support when selecting a generator supplier