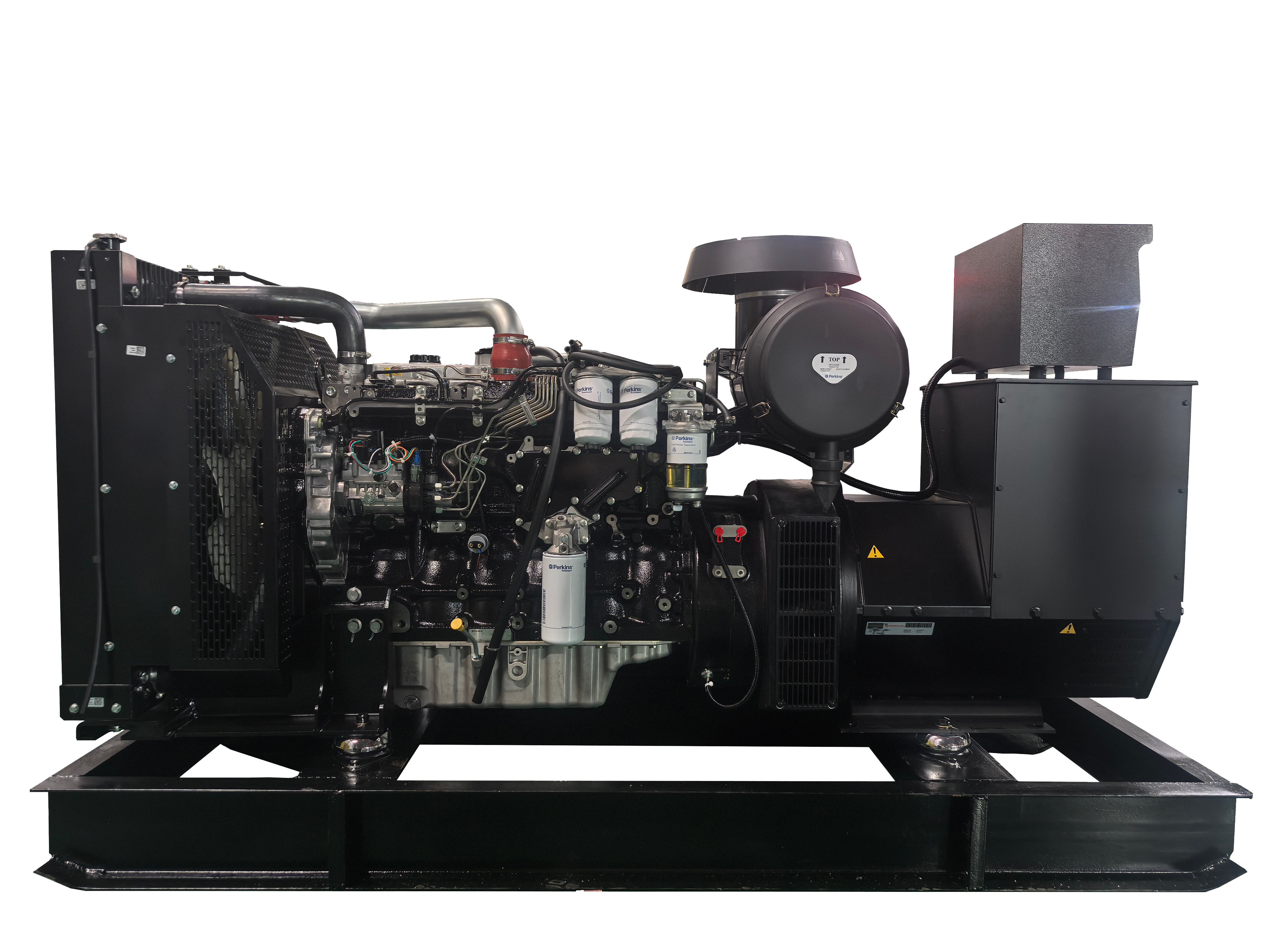

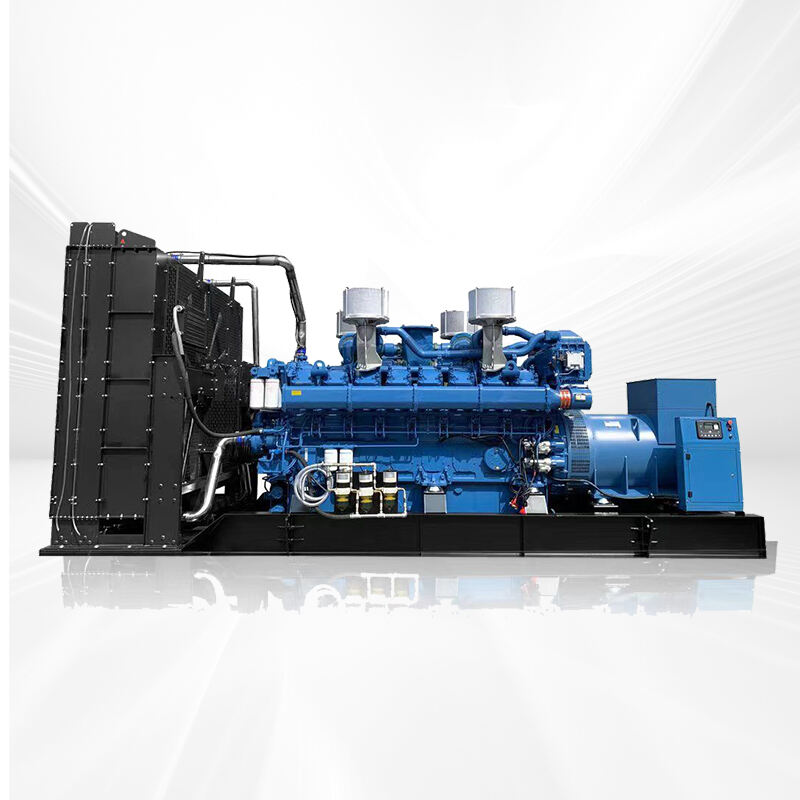

air cooled diesel generator

An air cooled diesel generator represents a crucial power solution that combines reliability with efficient cooling technology. This type of generator utilizes ambient air circulation to maintain optimal operating temperatures, eliminating the need for complex liquid cooling systems. The design features specialized fins and enhanced surface areas that maximize heat dissipation, ensuring consistent performance even under demanding conditions. These generators typically range from 2kW to 15kW, making them ideal for small to medium-scale applications. The system employs direct air flow across the engine block and components, managed by an integrated fan system that maintains consistent temperature control. Advanced models incorporate electronic governing systems that automatically adjust engine speed to match power demands, optimizing fuel efficiency and reducing wear. The air cooling mechanism simplifies maintenance requirements while ensuring reliable operation in various environmental conditions. These generators excel in applications where water resources are limited or when simplified maintenance is preferred, including remote locations, construction sites, and backup power for small commercial establishments.